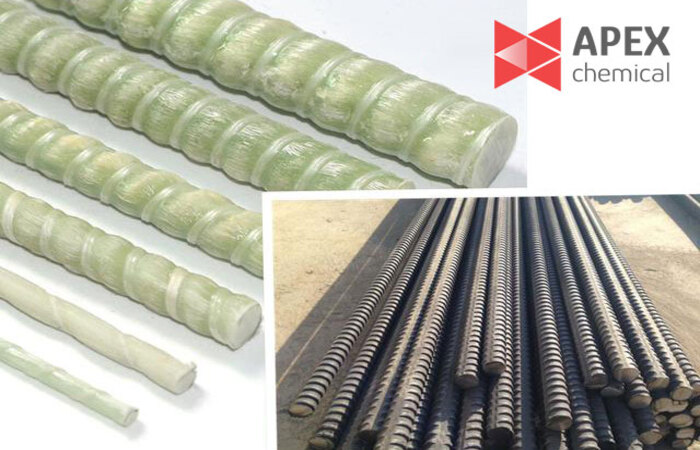

The difference between fiberglass bars and steel bars

Do you want to know the difference between fiberglass rebar and ordinary rebar? Who is more expensive between fiberglass bars and steel bars? Lap length of fiberglass rebar and rebar? Is fiberglass rebar steel? Can fiber tendons replace steel bars? Fiberglass bars vs. steel bars? This article will introduce the difference between glass fiber rebar and steel bar, including the difference in use, price, strength and construction.

The rapid development of glass fiber bars has a great relationship with the characteristics of glass fiber bars. Compared with ordinary steel bars, glass fiber bars have better physical properties and cost, and have better tensile strength, tensile modulus, and thermal insulation properties. There are great advantages in terms of transportation and operation costs.

1. In terms of use: glass fiber reinforcement is also called glass reinforcement material, commonly known as glass reinforcement or fiber reinforcement. Glass fiber reinforcement is basically similar to steel reinforcement in performance, has good adhesion to concrete, and has high tensile strength at the same time. And low shear strength, it can be easily cut directly by the composite shield machine without causing abnormal tool damage. Therefore, generally subway shields and temporary support of coal mine tunnels will choose fiber reinforcement.

2. In terms of construction period, compared with ordinary steel bars, fiberglass reinforcement is customized by the manufacturer. Since it cannot be processed on site, it is necessary to accurately control the size. Once the material is cut wrongly, the construction period will be delayed. Its shape is directly customized, which reduces the processing steps of ordinary steel bars, and the lap joint method of binding replaces the welding process, which saves the production time of the reinforcement cage. 2. In terms of construction period, compared with ordinary steel bars, fiberglass reinforcement is customized by the manufacturer. Since it cannot be processed on site, it is necessary to accurately control the size. Once the material is cut wrongly, the construction period will be delayed. Its shape is directly customized, which reduces the processing steps of ordinary steel bars, and the lap joint method of binding replaces the welding process, which saves the production time of the reinforcement cage.

3. In terms of construction difficulty, the flexural and shear bearing capacity of glass fiber reinforcement is much different from that of ordinary steel bars and its weight is lighter, so the stability of the reinforcement cage is not as good as that of ordinary steel cages in the lifting, lowering, and pouring projects of reinforcement cages. There are special situations such as loose cages, stuck cages, and floating, which require special attention in the production and hoisting of tendon cages.

4. In terms of construction safety, compared with the currently widely used construction method of partially or breaking the reinforced cage diaphragm wall at the shield end, the fiberglass reinforced cage diaphragm wall can be directly penetrated by the shield machine, avoiding the easy mud gushing It saves the cost of breaking the diaphragm wall, and also reduces the pollution of dust and noise.

5. In terms of economy, compared with ordinary steel bars, fiberglass bars are lighter, which reduces the cost of making the cages. At the same time, due to the larger size of the fiberglass cages, the width of the diaphragm wall is reduced, and the interface labor of the diaphragm wall is saved. The number of steel beams or locking tubes saves costs.

6. In terms of price: φ12 glass fiber reinforcement is more than 10,000 per ton, 5000 meters; steel bar is more than 4,000 per ton, 1100 meters; if the price is calculated from meters, the glass fiber reinforcement is lower than the steel bar; if the price is calculated from tons, the steel bar should be higher than fiberglass bars;

7. In terms of strength: the tensile strength of steel bars is 300-500MP, the tensile strength of glass fiber bars is 600-800MP, the tensile strength of glass fiber bars is better than that of ordinary steel, 20% higher than that of steel bars of the same specification, and the fatigue resistance is good;

8. Connection: steel bars can be welded, and glass fibers are lapped with U-shaped buckles

9. Coastal infrastructure: fiberglass reinforcement is non-corroding, light in weight, stronger in tensile strength than steel, and the disadvantage is that it is not strong in bending, so it is mostly used in coastal projects. Steel bars are easy to corrode, heavy in weight, inconvenient to transport, and have the advantage of better bending and greater elasticity.

10. Special purpose: glass fiber reinforcement is non-conductive, anti-magnetic wave, military, computer room, CT room and other architectural glass fiber reinforcement;

11. In terms of characteristics: fiberglass bars have high bearing capacity and strong tensile capacity. The strength of the rod body is twice that of threaded steel bars of the same diameter, but the quality is only 1/4 of that of steel bars; the elastic modulus is stable, about 1/3 to 1/3 of that of steel bars. 2/5; electrical and thermal insulation, thermal expansion coefficient is closer to cement than steel bars

12. The characteristics of alkali-resistant glass fiber are good alkali resistance, can effectively resist the erosion of high alkali substances in cement, strong grip, high elastic modulus, impact resistance, tensile and bending strength, non-flammable, frost-resistant, It has strong resistance to temperature and humidity changes, excellent crack resistance and impermeability, and has the characteristics of strong designability and easy molding. type reinforcement.

13. Application scope of glass fiber reinforcement:

·It can be widely used in highways, bridges, airports, docks, stations, water conservancy projects, underground engineering and other fields;

Suitable for use in corrosive environments such as sewage treatment plants, chemical plants, electrolyzers, manhole covers, and coastal defense projects;

Suitable for use in military engineering, security engineering, special engineering and other environments that require insulation and demagnetization;

14. Characteristics of glass fiber reinforcement:

High tensile strength: the tensile strength is better than that of ordinary steel, 20% higher than that of steel bars of the same specification, and it has good fatigue resistance;

Light weight: only 1/4 of the same volume of steel bars, the density is between 1.5-1.9 (g/cm3):

Strong corrosion resistance: Corrosion of chemicals such as acid and alkali can resist the corrosion of chloride ions and low PH value solutions, especially the corrosion resistance of carbon compounds and chlorine compounds;

Strong material bonding force: The thermal expansion coefficient is closer to that of cement than steel, so the bonding force between FRP reinforcement and concrete is stronger;

·Strong designability: the elastic modulus is stable. Stable size under thermal stress, bending and other shapes can be arbitrarily thermoformed; good safety performance, non-thermal, non-conductive, flame-retardant and anti-static, and no sparks will be generated by changing the formula when it collides with metal;

Strong magnetic wave permeability: FRP bar is a non-magnetic material, and it does not need to be demagnetized in non-magnetic or electromagnetic concrete components;

·Convenient construction: standard and non-standard parts with different sections and lengths can be produced according to user requirements, and non-metal tensioning belts can be used for on-site binding, which is easy to operate.

15. Strong corrosion resistance: Corrosion of chemicals such as acid and alkali can resist the corrosion of chloride ions and low pH solution, especially the corrosion resistance of carbon compounds and chlorine compounds;

16. Strong material bonding force: The thermal expansion coefficient is closer to that of cement than steel, so the bonding force between FRP reinforcement and concrete is stronger.

17. Strong design: the elastic modulus is stable. Stable dimensions under thermal stress, bending and other shapes can be arbitrarily thermoformed; good safety performance, non-thermal, non-conductive, flame-retardant and anti-static, and no sparks will be generated by changing the formula when colliding with metals;

18. Strong magnetic wave performance: FRP bar is a non-magnetic material, and it does not need to be demagnetized in non-magnetic or electromagnetic concrete components;

19. Convenient construction: standard and non-standard parts of various sections and lengths can be produced according to user requirements, and non-metal tensioning belts can be used for on-site binding, which is easy to operate.

20. Lap length: The lap length of glass fiber reinforcement and steel bar is not less than 20D. For example, if fiber reinforcement with φ20mm is used, the lap length should not be less than 40cm.

What is the difference between fiberglass rebar and ordinary rebar?

The rapid development of glass fiber bars has a lot to do with the characteristics of glass fiber bars. Compared with ordinary steel bars, glass fiber bars have better physical properties and cost, and have better tensile strength, tensile modulus, and thermal insulation. There are great advantages in terms of performance and transportation operating costs.

1. In terms of construction period, compared with ordinary steel bars, fiberglass reinforcement is customized by the manufacturer. Since it cannot be processed on site, it is necessary to accurately control the size. Once the material is cut incorrectly, the construction period will be delayed. Its shape is directly customized, which reduces the processing steps of ordinary steel bars, and the lap joint method of binding replaces the welding process, which saves the production time of the reinforcement cage.

2. In terms of construction difficulty, the flexural and shear bearing capacity of glass fiber reinforcement is much different from that of ordinary steel bars and its weight is lighter, so the stability of the reinforcement cage is not as good as that of ordinary steel cages in the lifting, lowering, and pouring projects of reinforcement cages. There are special situations such as loose cages, stuck cages, and floating, which require special attention in the production and hoisting of tendon cages.

3. In terms of construction safety, compared with the currently widely used construction method of partially or breaking the reinforced cage diaphragm wall at the shield end, the fiberglass reinforced cage diaphragm wall can be directly penetrated by the shield machine, avoiding the easy mud gushing It saves the cost of breaking the diaphragm wall, and also reduces the pollution of dust and noise.

4. In terms of economy, compared with ordinary steel bars, fiberglass bars are lighter, which reduces the cost of making the cages. At the same time, due to the larger size of the fiberglass cages, the width of the diaphragm wall is reduced, and the interface labor of the diaphragm wall is saved. The number of steel beams or locking tubes saves costs.

High tensile strength: The tensile strength is better than that of ordinary steel, 20% higher than that of steel bars of the same specification, and it has good fatigue resistance;

Light weight: only 1/4 of the same volume of steel bars; density between 1.5-1.9 (g/cm3).

Strong corrosion resistance: The corrosion resistance of chemicals such as acid and alkali can resist the corrosion of chloride ions and low pH value solutions, especially the corrosion resistance of carbon compounds and chlorine compounds;

Strong material bonding force: The thermal expansion coefficient is closer to that of cement than steel, so the bonding force of FRP reinforcement and concrete is stronger.

Strong design: the elastic modulus is stable. Stable dimensions under thermal stress, bending and other shapes can be arbitrarily thermoformed; good safety performance, non-thermal, non-conductive, flame-retardant and anti-static, and no sparks will be generated by changing the formula when colliding with metals;

Strong magnetic wave permeability: FRP bar is a non-magnetic material, and it does not need to be demagnetized in non-magnetic or electromagnetic concrete components;

Convenient construction: standard and non-standard parts with different sections and lengths can be produced according to user requirements, and non-metal tensioning belts can be used for on-site binding, which is easy to operate.

What is the difference between fiberglass rebar and rebar?

Glass fiber reinforced plastic: a composite material made of high-strength glass fiber as a reinforcing material, synthetic resin as a matrix material, and mixed with an appropriate amount of auxiliary agents, called glass fiber reinforced plastic (English abbreviation: FRP), commonly known as glass fiber reinforced plastic. There are mainly “glass fiber rebar” and “basalt fiber rebar”. (Φ6mm~Φ36mm)

Reinforcing bar (also known as ribbed steel) is a kind of steel bar, which is a kind of building material. For example in reinforced concrete, the skeleton used to support the structure. Including smooth round bars, ribbed bars, torsion bars. There are many types of rebar, usually classified by chemical composition, production process, rolling shape, supply form, diameter size, and use in the structure. Reinforcing bars are mainly subjected to tensile stress in concrete. Due to the action of ribs, deformed steel bars have greater bonding ability with concrete, so they can better withstand the action of external forces. Steel bars are widely used in various building structures, especially large, heavy, light thin-walled and high-rise building structures.

Glass fiber: also known as alkali-resistant glass fiber, alkali-resistant glass fiber is a rib material of glass fiber reinforced (cement) concrete (referred to as GRC), an inorganic fiber, and an ideal substitute for steel and asbestos in non-load-bearing cement components . The characteristics of alkali-resistant glass fiber are good alkali resistance, can effectively resist the erosion of high alkali substances in cement, strong gripping force, high elastic modulus, impact resistance, tensile and bending strength, non-flammable, frost-resistant, temperature-resistant , strong humidity change ability, excellent crack resistance, impermeability, strong designability, easy molding and other characteristics, alkali-resistant glass fiber is a new type of green and environmentally friendly reinforcement widely used in high-performance reinforced (cement) concrete Material.

Glass fiber reinforcement application range:

1. It can be widely used in highways, bridges, airports, docks, stations, water conservancy projects, underground engineering and other fields;

2. Suitable for use in corrosive environments such as sewage treatment plants, chemical plants, electrolytic cells, manhole covers, and coastal defense projects;

3. Suitable for use in military engineering, security engineering, special engineering and other environments that require insulation and demagnetization;

Fiberglass rib features:

1. High tensile strength: the tensile strength is better than that of ordinary steel, 20% higher than that of steel bars of the same specification, and has good fatigue resistance; 2. Light weight: only 1/4 of the same volume of steel bars, with a density of 1.5-1.9 (g/cm3): 3. Strong corrosion resistance: corrosion resistance of chemicals such as acid and alkali can resist the corrosion of chloride ions and low PH value solutions, especially the corrosion resistance of carbon compounds and chlorine compounds is stronger; 4 . Strong material bonding force: The thermal expansion coefficient is closer to cement than steel, so the bonding force of FRP reinforcement and concrete is stronger; 5. Strong designability: the elastic modulus is stable. Stable size under thermal stress, bending and other shapes can be arbitrarily thermoformed; good safety performance, non-thermal, non-conductive, flame-retardant and anti-static, no sparks will be generated by collision with metal through formula changes; 6. Strong magnetic wave permeability: FRP ribs The material is a non-magnetic material, and there is no need for demagnetization treatment in non-magnetic or electromagnetic concrete components; 7. Convenient construction: standard and non-standard parts of various sections and lengths can be produced according to user requirements, and can be used for on-site binding Non-metal tensioning belt, easy to operate.

Rebar production requirements:

When the steel bar is processed and produced, the steel bar processing table and the design drawing should be reviewed, and the blanking table should be checked for errors and omissions. The actual samples are released from the table, and the batches can be produced only after the trial production is qualified. The processed steel bars should be listed and stacked in an orderly manner.

If replacement of steel bars is required during construction, it is necessary to fully understand the design intent and the properties of the replacement materials, strictly abide by the various provisions of the current reinforced concrete design specifications, and do not replace low-strength steel bars with high-strength steel bars of the same area. The replacement of steel bars in important parts shall be subject to the consent of Party A and the design unit, and can be replaced only when there is a written notice.

(1) The surface of the steel bar should be clean, and the adhered oil, soil and rust must be cleaned before use, and the rust can be removed by combining with the cold drawing process.

(2) The steel bar can be straightened mechanically or manually. The straightened steel bars shall not have local bending, dead bends or small waves, and the surface scars shall not reduce the cross-section of the steel bars by 5%.

(3) The steel bar should be cut according to the number, diameter, length and quantity of the steel bar, and the length should be matched. The long material should be cut first and then the short material should be broken, and the short end of the steel bar should be minimized and shortened to save steel.

(4) Rebar hooks or bends:

①Rebar hook. There are three forms, namely semi-circular hook, straight hook and oblique hook. After the steel bar is bent, the inner skin shrinks, the outer skin extends, and the length of the axis remains unchanged at the bending place, and an arc is formed at the bending place. The size after bending is not larger than the blanking size, and the bending adjustment value should be considered.

The diameter of the bending center of the steel bar is 2.5d, and the straight part is 3d. The theoretical calculation value of the increased length of the steel bar hook: 6.25d for the half-circle hook, 3.5d for the straight hook, and 4.9d for the oblique hook.

②Bend the steel bar. The bending diameter D of the bending part of the middle part is not less than 5 times the diameter of the steel bar.

③ stirrups. The ends of the stirrups should be hooked, and the hook form should meet the design requirements. Stirrup adjustment, that is, the difference or sum of the added length of the hook and the bending adjustment value, depends on the outer size or inner size of the stirrup.

④The cutting length of the steel bar should be comprehensively considered according to the size of the component, the thickness of the concrete protective layer, the adjustment value of the bending of the steel bar and the length of the hook.

a. Straight steel bar cutting length = member length – protective layer thickness + hook increase length,

b. Bending steel bar cutting length = straight section length + oblique bending length – bending adjustment value + hook increase length,

c. Stirrup cutting length = stirrup inner circumference + stirrup adjustment value + hook increase length.

Rebar processing

Rebar processing generally goes through four processes: rebar rust removal; rebar straightening; rebar cutting; rebar forming.

When the steel bar joints are connected with straight threads or conical threads, the upsetting and thread processing procedures of the steel bar ends are also added. Rebar batching and substitution.

steel bar replacement

(1) When replacing the steel bars specified in the design documents with steel bars of another steel grade or diameter, the following provisions shall be observed:

It should be carried out according to the principle of equal design value of steel bearing capacity, and after the replacement of steel bars, it should meet the specified structural requirements such as steel bar spacing, anchorage length, and steel bar diameter.

When replacing lower-grade steel bars with higher-grade steel bars, it is advisable to use the method of changing the diameter of the steel bars instead of the method of changing the number of steel bars to reduce the cross-sectional area of the steel bars.

(2) When replacing a steel bar of a certain diameter with the same steel grade, the diameter variation range should not exceed 4mm, and the ratio of the total cross-sectional area of the steel bar after the change to the cross-sectional area specified in the design document should not be less than 98% or greater than 103% .

(3) When the design main reinforcement is replaced with the same steel grade, the spacing should be kept unchanged, and two types of reinforcement with a diameter larger or smaller than the designed reinforcement diameter can be used for substitution.